Technology in fashion, technological fashion and technology for fashion.

I wouldn’t call myself someone that follows fashion trends. That being said, I do go to stores and pick out things I like, therefore it is unavoidable to become part of fashion on-goings, and to build preferences. I have favourites that I wear and re-wear, until they wear out or stop agreeing with my figure. I also have a cupboard corner full of non-essentials I picked up because they seemed ‘cute’ at the time or were on sale. Safe to say, I follow fashion trends unconsciously.

In this post, I aim to look at the involvement of technology in the life-cycle of single piece of fabric; from the time its fibres are woven, to the construction of a garment, and then to where and/or how its thrown away.

Technology in fashion:

There are so many different types of fabric. More so now, than ever, due to technology that allows us to produce ‘blended’ fabrics. Natural fibres are sourced from plants and animals and require manual techniques for separation. They then have to be recombined before they can be woven into usable fabric. Synthetic fibres, on the other hand, are scientifically developed from chemicals such as petroleum, and require a lot of technical processing before they’re turned to thread.

The main idea of blended fabrics is to combine fibers with certain qualities with fibers of other qualities that compliment each other. Cotton and polyester are an example of blended fabrics. Cotton is comfortable to wear, however, it wrinkles easily. On the other hand, Polyester does not wrinkle. A combination of the two results in a comfortable and wrinkle-resistance fabric. Voila!

Technology is not only involved in binding and weaving these fibres together, it now also a part of the garment making process.

I cant remember the last time saw brands create collections for just the four seasons. I’ve come across advertisements for summer collection volume 1s and volume 2s, mid-summer collections, summer-was-hot-this-year collections, summer’s-almost-over collections and can’t-wait-for-next-summer collections. This is the fruit of fast fashion.

Designs are able to move quickly from catwalk to store shelves. Retailers are able to spot new trends and deploy their insanely quick design, thanks to fast and advanced fabric-cutting and sewing machines.

And so, fast-fashion is now on-going and flourishing, with thousands of styles being produced per week, and millions of tons of textile being discarded each year.

Technological fashion:

I was introduced to the works of Hussein Chalayan, and I think there’s no better example than his 2007 Spring/Summer collection, to encapsulate the essence of this section of the blog. Take a look:

The self-transforming robotic garments were nothing short of a mesmerizing piece of art. The way Chalayan implements technology in his work, is as if the purpose is to establish an interaction between the garments and the body, between human and nonhuman aspects. His designs were a live metamorphosis of styles from different decades converting into the decade ahead.

The collection, entitled ‘One Hundred and Eleven’, started with a full-length, high-necked Victorian gown that transformed from a calf-length 1910s dress into a beaded flapper dress from the 1920s.

Memory and Materiality in Hussein Chalayan’s Techno-Fashion by Lianne Toussaint and Anneke Smelik

Technology aided historical story-telling through fashion. Genius!

Here’s an example of technological advances helping with sustainable design. If you thought that coffee grounds are organic waste, therefore are biodegradable, and are wondering why it should be recycled, read this: https://maartedu2020.wordpress.com/2020/06/20/biodegradability-is-not-enough/

The ECOALF FOUNDATION is a non-profit organisation whose main objective is to promote the selective recovery of waste in order to recycle, valorise and avoid its harmful effects on the environment by developing and applying new scientific and technological knowledge.

from ECOALF’s website

Technology for fashion:

Now that we’re on the subject of sustainability, we can all agree that the culture of fast fashion is doing the exact opposite. with many people viewing their clothing as discardable, the textile waste produced is unimaginable. A lot of individuals and organizations have taken steps to re-cycle fabric but that too becomes extremely difficult when when brands aren’t upfront about types and blends of materials they’ve used to construct their pieces.

This problem that technology may have caused, may also be solved by technology. A ‘fibre sort machine’ has been developed by Wieland Textiles and Valvan Baling Systems.

The machine can scan and sort clothing based upon its material contents, making what was once an inefficient and difficult process – relying on touch and sight – efficient and swift.

https://christienmeindertsma.com/Fibre-Market

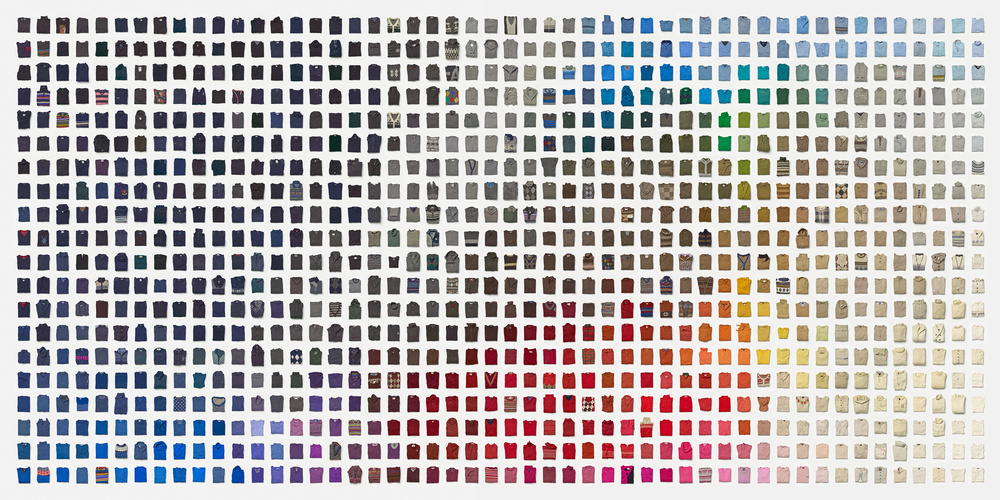

From the picture above, the sorting machine not only sorted a 1000 sweaters by their material content, it also sorted them by colour! What a visual treat. Christien Meindertsma, a Dutch artist and designer, then went through the scanned results and compared them to the labels on the products, and found a high proportion of inaccuracy between the two.

After the sorting process, the sweaters are shredded down, so that they can be used to generate fabric again. The fibres of the sweaters were piled like spices at the spice bazaar. Perhaps that’s why Meindertsma called it the ‘Fibre Market’.